Category

D28 D32 H15 Metal Laser Cutting Nozzle for CNC Fiber Laser Cutting Machine Parts for Precitec Raytools Wsx Head with Single Double Layer Chrome Plating Copper

Package Size 15.00cm * 5.00cm * 2.00cm Package Gross Weight 0.500kg Lead Time 5 days (1 - 10 Pieces) 10 days (11 - 100 P

Basic Info.

| Model NO. | D28/D32 H15/H11 |

| Standard Component | Standard Component |

| Type | Cutting Nozzle |

| Laser Scanner Head | Fiber Laser Marker/Engraver/Cutter/Printer/Cut |

| Fiber Laser Source Price | 0.8/1.0/1.2/1.5/2.0/2.5/3.0/3.5/4.0/4.5/5.0mm |

| Fiber Laser Controller | Laser Cutting/Engraving/Marking/Printing Machinery |

| Laser Machine Lens Price | 4kw Raycus Laser Source/Ceramics Contact Ring/40W |

| Ipg Laser Source Price | Cypcut 1000/2000/3000;Ruida;Weihong; |

| Fiber Laser Power Source | Rotary/Micro Controllers/Laser Engraver Parts |

| Fiber Laser Source | Water Cooling Chiller Machine |

| Laser Module | 3000*1500mm;4000*2000mm; 6000*2000mm; 6000*2500mm; |

| Fiber Laser Cutting Head | 1500W/4000W/5000W/7000W/8000W/10000W/12000W/20000W |

| Laser Head | Steel Sheet/Tube/Plate/Pipe/Stencil/Die Board |

| Laser Lens | Raycus/ Jpt/ Max/ Ipg/ Lianpin/ Super Laser/Feibo |

| Laser Cutting Lens | Protective Lens/Focus Lens/Reflective Lens |

| Chrome Plating | Raytools Laser Head 3kw/Source Laser Fiber 1000W |

| Laser Cutting Head | Carbon Steel; Stainless Steel; Aluminium; Copper |

| Cutting Nozzle | Wholesale/Agent/Factory Price for Sale |

| Transport Package | Carton |

| Specification | 28mm/32mm Dia*15mm Height |

| Trademark | OEM /Precitec/ Raytools/ Wsx |

| Origin | China |

| HS Code | 8466939000 |

| Production Capacity | 100000 Sets Per Month |

Packaging & Delivery

Package Size 15.00cm * 5.00cm * 2.00cm Package Gross Weight 0.500kg Lead Time 5 days (1 - 10 Pieces)10 days (11 - 100 Pieces)

15 days (101 - 1000 Pieces)

To be negotiated ( > 1000 Pieces)

Product Description

CCI LASER Metal CNC Fiber Laser Cutting MachineHigh cutting efficiency, high cost performance and low running costHigh cutting performance for copper/brass, aluminum, stainless steel and carbon steel 1. Feature:1.1 Materail: Imported copper;1.2 Working Temperature: High Temperature Resistance;1.3 Working Pressure: High Pressure Resistance;1.4 Installation Method: External Screw Thread.

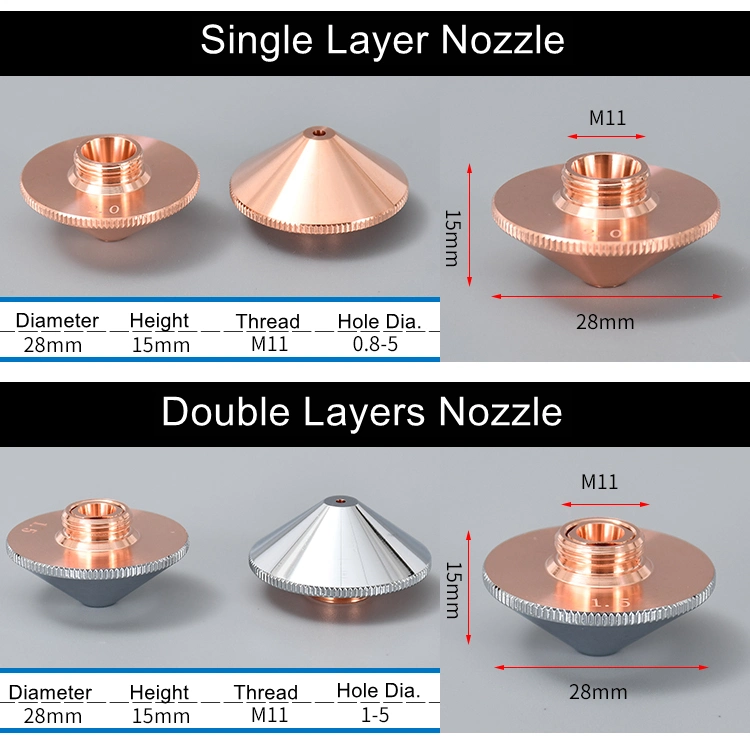

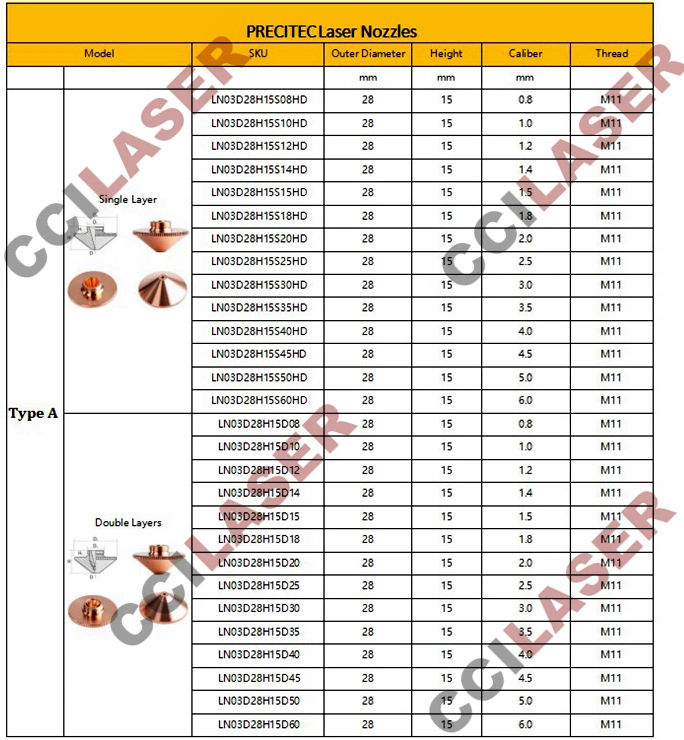

2. Technical Parmeters

| Item | Outer Diameter | Height | Caliber | Thread |

| Single Layer Laser Cutting Nozzle (Chrome Plating/ Withou Chrome Plating) | 28mm | 15mm | 0.8/1.0/1.2/1.5/2.0/2.5/3.0/3.5/4.0/4.5/5.0mm | M11 |

| Double Layer Laser Cutting Nozzle (Chrome Plating) | 28mm | 15mm | 0.8/1.0/1.2/1.5/2.0/2.5/3.0/3.5/4.0/4.5/5.0mm | M11 |

3. More Detailed Information about cutting nozzle

4. Package

CCILASER Company Advantage:

Delivery time is guaranteed.

15000m3 laser equipment processing workshop. 300-500 laser marking machines are inspected and accepted every month.

Reasonable production management process to ensure the machine quality.

110 Professional and technical workers.Every front-line production worker has undergone strict pre-job training.One worker only completes one process of product production to ensure the production of high-quality products. Each process is inspected to ensure the accumulative accuracy of the product.

Supports ODM and OEM.

12 technical R&D persons.We provide different solutions for different industries, so as to meet the technical requirements of different industries as much as possible.

Perfect after-sales service system.

35 after-sales service personnel with more than ten years working experience. 2-3 engineers are responsible for one area to ensure the professional and timely debugging work, so that users can put into production as soon as possible. Every year we hold a quality journey, visit new and old users everywhere, help them to check the machine and listen to the actual needs of customers, so as to do a good job of market research for our product technology upgrade.

Complete pre-sale service network.

86 pre-sales engineers are distributed in all corners of the world, providing different solutions for users in all walks of life.

5.Related Laser Machine Parts

5.1 Safety Lens

5.2 Ceramic Loop

Company and Products Advantage:

Delivery time is guaranteed

15000m3 laser equipment processing workshop. 100-150 laser cutting machines are inspected and accepted every month.

Reasonable production management process to ensure the machine quality.

110 Professional and technical workers.Every front-line production worker has undergone strict pre-job training.One worker only completes one process of product production to ensure the production of high-quality products. Each process is inspected to ensure the accumulative accuracy of the product.

Supports ODM and OEM.

12 technical R&D persons.We provide different solutions for different industries, so as to meet the technical requirements of different industries as much as possible.Complete pre-sale service network.The CCILASER pre-sales consulting team will wholeheartedly provide you with laser machinery consulting, solutions and other services. 86 pre-sales engineers are distributed in all corners of the world, providing different solutions for users in all walks of life.Perfect after-sales service system.35 after-sales service personnel with more than ten years working experience will be on standby 7*24 hours, all year round, fully guaranteeing the worry-free use of your products and the stable operation of your business.2-3 engineers are responsible for one area to ensure the professional and timely debugging work, so that users can put into production as soon as possible. Every year we hold a quality journey, visit new and old users everywhere, help them to check the machine and listen to the actual needs of customers, so as to do a good job of market research for our product technology upgrade.1. Guarantee for the whole machine: 24-60 months2. Providing professional service to customers, any call for technical help will be solved in 24 hours 3. Free training, free maintenance and free technical support within warranty period4. We supply life-long free service in technical upgrading.

CCI Laser Machines Series

CCILASER FactoryABOUT US

CCI Laser·Global laser smart solution expert

CCI Laser Group has been deeply engaged in the manufacturing of laser intelligent equipment for 18 years. It is headquartered in Jinan, China and has two wholly-owned subsidiaries. It is a national high-tech enterprise focusing on laser application solutions such as laser cutting, tube cutting, precision cutting, laser welding, laser marking, CNC bending, and automation equipment.

CCI Laser has established branches and service outlets in 20% of the countries and regions around the world to promote the process of global intelligence and has more than 100 patents and certificates.

CCI Laser adheres to the quality route and forms 89 production and inspection procedures higher than the industry standard. With the mission of "Laser technology serves for user production, supplying complete solutions, improving user working way", its high-quality products and after-sales service have won high praise from customers, and repurchase rate >95%.

Wish cooperating with you to create a better future!

CCILASER Production and Quality Inspection

CCILASER Qualification Certification

CCILASR all machines come with 2-5 years warranty, and we have the certifications of ISO9001, BV, CE, ect.

Exporting Package and DeliveryThe normal package is wooden pallet and wooden case. The wooden pallet and wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.FAQ

Q1: What will you do to control machine quality before shipment?

1. Test of cutting size and precision (1000mm size pattern error cannot exceed 0.02mm)2. Closed graphic closure test (The start and end points of the graph are completely coincident)3. Small circle speed test (Small circle with a diameter of 1mm, cutting speed is 30mm/s)4. 72 hours uninterrupted aging test

Q2: When I got this machine, but I don't know how to use it. What should I do? Our technician have installed the machine before shipping. For some small parts installation, English detail training manual & video will be sent out together to you with the machine. 95% customers can learn by themselves. If you still need any further helps, our engineer can also guide you via wechat, whatsapp, skype or video conference for free. If still not workable, our engineer can go aboard to guide you, some charge is needed.Q3:If some problems happen to this machine during warranty period, what should I do?If confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We will response within 24 hours as quickly as we can to solve it for you.When customer supply picture & video, free parts will be supplied during machine warranty period if machine have some problems. While we also supply free life long after-sales service. So any doubts, just let us know, we will give you solutions.Q4: What's the package? Will the package damaged during transportation?

A: We have 3 layers package. For the outside, we adopt wood craft case or steel frame to fix the laser cutting machine. In the middle, the machine is covered by thickening plastic bag for waterproof. For the inside layer, the machine is covered by wrapped plastic film.Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe transportation. We have exported to 160 countries worldwide. So please don't worry, you will receive the parcel in good condition.

CCILASER Product quality has been well received by the international market.CCILASER products have been exported to more than 160 countries and regions and have been well received by users.We establish offices in the United States, Brazil, India, Russia, Spain, Turkey, Thailand, Malaysia and other countries. In order to adapt to the continuous expansion of the company's business and further improve the quality of after-sales service, we sincerely invite local distributors to join our sales and service system, and work together to support perfect sales and after service for users.Please advise us the following information, then we can recommend you the most suitable model, right now, don't hesitate to contact us-China CCI Laser!1. The exact material you want to cut? (Stainless steel, carbon steel, mild steel, etc.)2. The cutting depth on above materials? (max thickness, 3 mm, 5 mm, 7 mm, 15 mm....)3. The working area you demand? (max dimension of material, width*length, 1500*3000 mm...)Quality is our culture! Your satisfaction is our motivation!Need more information please feel free to contact us-CCI Laser! Right Now!!