Plastic Process Injection Molding 9kw Hot Runner Mould Temperature Control Water Type Mold Temperature Controller

Basic Info.

| Model NO. | XC-TM9KW-W |

| Display Type | LCD |

| Main Pipe | Stainless Steel |

| Loading Distance | 38 M |

| Warranty | 1 Year |

| Operating Principle | Direct or Indirect as Required |

| Control Type | Digital |

| Transfer Medium | Water |

| Pump Flow | 56 L/Min |

| Pump | 0.75 Kw |

| Heating Power | 9kw |

| Max. Temp | 100 Degree |

| Transport Package | Wooden Case as Usual |

| Specification | 730x310x643 mm |

| Trademark | XIECHENG |

| Origin | China |

| HS Code | 8419899090 |

| Production Capacity | 500pieces Per Month |

Packaging & Delivery

Package Size 73.00cm * 31.00cm * 64.30cm Package Gross Weight 46.000kgProduct Description

Plastic Process Injection Molding 9kw Hot Runner Mould Temperature Control Water Type Mold Temperature Controller

Product Description

Water Mold Temperature Controller

Water heaters are used to heat up the mould and maintain temperature, and also they can be used in other similar applications. This series of machines use water as the medium that saves production cost and ensures good working environment. As water circulates in the hermetic pipes, it remains in liquid state even the mould temperature is higher than 100°C, which can enhance flow rate and improve heat transfer effect.

Product Specifications

| Model | XC-TM6KW-W | XC-TM9KW-W | XC-TM12KW-W | XC-TM18KW-W | XC-TM24KW-W | XC-TM36KW-W |

| Transfer Medium | Water | |||||

| Maximum Temperature | 100°C | |||||

| Pump (KW) | 0.37 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 |

| Pump Flow (L/min) | 42 | 56 | 56 | 160 | 160 | 315 |

| Loading Distance (m) | 28 | 38 | 38 | 27 | 27 | 30 |

| Heating Power (KW) | 6 | 9 | 12 | 9*2 | 12*2 | 12*3 |

| Inlet and Outlet Diameter | 3/8``x2 | 3/8``x4 | 3/8``x4 | 1''x1 | 1''x1 | 1.5``x1 |

| Dimensions (mm) | 730*310*643 | 730*310*643 | 730*310*643 | 830*370*694 | 830*370*694 | 1090*520*983 |

| Approx. Net Weight (KG) | 45 | 46 | 50 | 65 | 100 | 110 |

If you want more sizes, please contact us for details

CONTACT SUPPLIER

Product Actual Shooting

Product Details

01 LCD controller

▪ Advanced microcomputer LCD controller can display both the actual temperature and set temperature, easy to operate with accuracy ±0.1 Celsius and long continuity and high efficiency.▪ Digital timing for 24 hours a week to realize automatic operation.

02 Siemens Electric

SIEMENS electrical parts ensures stable running and liability of the machine.

03 Water Pump

Adopted with high efficiency water pump. It can keep accurate temperature level and it is adaptable for production with precise molding.

04 Heating Wire

Using SUS304 seamless heating wire, stainless steel flange, not easy to burn out, durable.

05 Radiator Pipe & Barrel

▪ Using pure copper heat pipe, the heat dissipation effect is better;▪ The radiator barrel is made of stainless steel, corrosion resistance and long life.

06 SUS304 stainless steel seamless

SUS304 stainless steel seamless heating barrel and main pipelines can ensure corrosion-resistant, no leakage and long working lifetime.

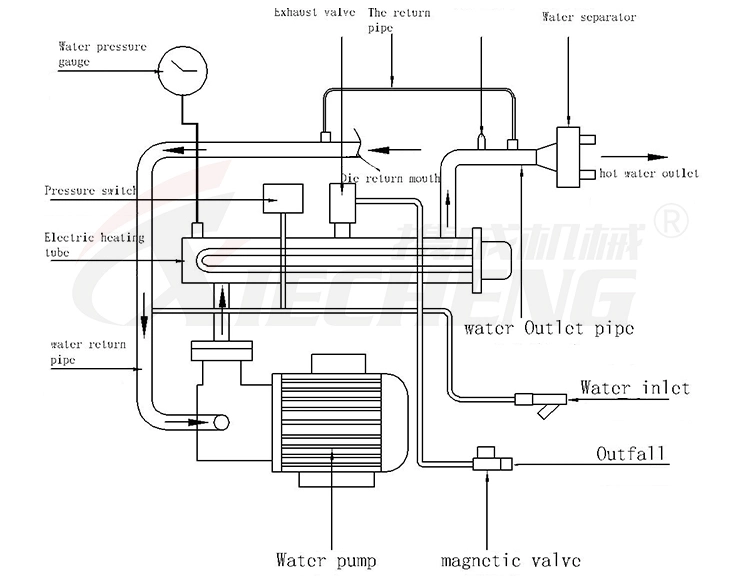

Working Principle

Customer Case

Widely used for plastic molding, Die casting of light guide plate, rubber tire,roller, chemical reaction kettle, adhesive industry, plastication and mixing industry etc.

About Us

Company ProfileIn 2009, founded by Mr. Fuzhibo with its head quarter in Jiangmen city which known as a famous hometown of many overseas Chinese, Jiangmen Xiecheng Machinery Co., Ltd. has been devoted herself to be an integrated enterprise of R&D, manufacturing and marketing businesses for High-end Industrial Refrigeration Equipment, Rubber and Plastic Moulding Auxiliary Automation Equipment, and also Intelligent Integrated System Solutions. Authenticated by IS09001, XIECHENG also successfully established the "6+1+C" full dimensional product service system with her own supply chain advantages of combining the six series of products, as Industrial Refrigeration, Mould Temp. Controlling, Material Conveying, Crushing & Recycling, Dehumidifying & Drying, and also Mixing, into central intelligent system solutions as Material Feeding, Air Supply, Water Supply and Power Supply, to fast fitting customers' specific demands.

Exhibition